Basic Info

Model No.: Customized

Click on the follow link to find out more information: https://www.hnyongrongglobal.com/rotor-core-by-aluminum-centrifugal-casting/

Company Info

- Company Name: Henan Yongrong Power Co., Ltd

- Representative: ZHUXIAODONG

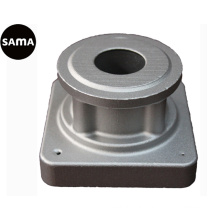

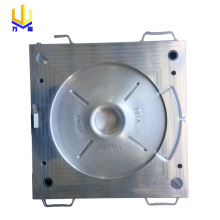

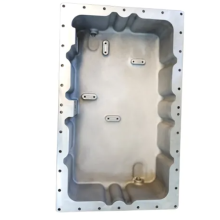

- Product/Service: Stator Lamination , Stator Core , Rotor Core , Motor Core , Motor Lamination , Generator Lamination

- Capital (Million US $): 60,000,000RMB

- Year Established: 2009

- Total Annual Sales Volume (Million US $): US$50 Million - US$100 Million

- Export Percentage: 11% - 20%

- Total Annual Purchase Volume (Million US $): US$50 Million - US$100 Million

- No. of Production Lines: Above20

- No. of R&D Staff: 11 -20 People

- No. of QC Staff: 11 -20 People

- OEM Services Provided: YES

- Factory Size (Sq.meters): Above 100,000 square meters

- Factory Location: South of weiwu road, Changge, Henan, China. 461500

- Contact Person: Mr. Jerry Zhu

- Tel: +86-0374-6566166

Premium Related Products

Other Products

Hot Products

CNC Machining Part (BIXMH2011-2)Injection Parts, Plastic Injection PartsHigh Precision Machining Part Casting Parts CNC MachiningMachining Part, CNC Machining, Turning PartDie Casting, Die Casting Part, Aluminum CastingAluminum sand casting part of metal brackets for woodgerman auto partscasting iron for gearsaluminum sand casting/stamping/pressingshaftsSand casting servicesGravity Aluminum Casting PartsPreision aluminum die castingprecision stainless steel gear wheellathe partsmetal stamping parts