Introduction to the composition of welding robots

2021-07-04

Welding robot is an indispensable automatic welding equipment in modern industry. The emergence of welding robot not only solves the problem of people's working environment, but also improves the production efficiency and welding quality. Do you know what the composition of welding robot is? Let's take a look!

Welding robot composition

Introduction about the composition of welding robots: Using welding robots to perform operations is a trend in the development of manufacturing. Welding robots are an important symbol of modern factories. Nowadays, more and more companies will choose welding robots to perform operations. With robots for welding, it is not enough to have a robot and there must be peripheral equipment. The conventional welding robot system consists of the following five parts.

1. The robot body, generally a 6-axis articulated manipulator driven by a servo motor, is composed of a driver, a transmission mechanism, a robot arm, a joint, and an internal sensor. Its task is to precisely ensure the required position, posture and trajectory of the end of the manipulator.

2. The robot control cabinet, which is the nerve center of the robot system, includes computer hardware, software, and some special circuits. It is responsible for handling all the information in the robot's working process and controlling all its actions.

3, welding power system, including welding power, special welding torch

4, welding sensors and system security protection facilities.

5, welding fixture. For small batches of products of various types, sizes, or masses, simple welding robot workstations or robot workstations combining robots and robots can be used, depending on the spatial distribution of the workpiece's welds.

About the introduction of the composition of the welding robot is introduced, the welding robot can form a production line to carry out batch welding work, the company adopts the welding robot to carry out the operation, greatly reduces the company's capital investment, reduces the occurrence of security risks, is less investment, high efficiency Low-cost investment,.

Welding Robot are currently being widely used in the areas of defense, shipbuilding, marine technology, chemical equipment production, pressurized vessel manufacturing and nuclear power installations.

We design our products to meet the specifications of process flow, while taking into consideration the restrictions of cutting and welding. Our products are equipped to solve the numerous problems which arise in equipment fabrication, such as making accommodations for nonstandard work piece sizes and incorrect locations.

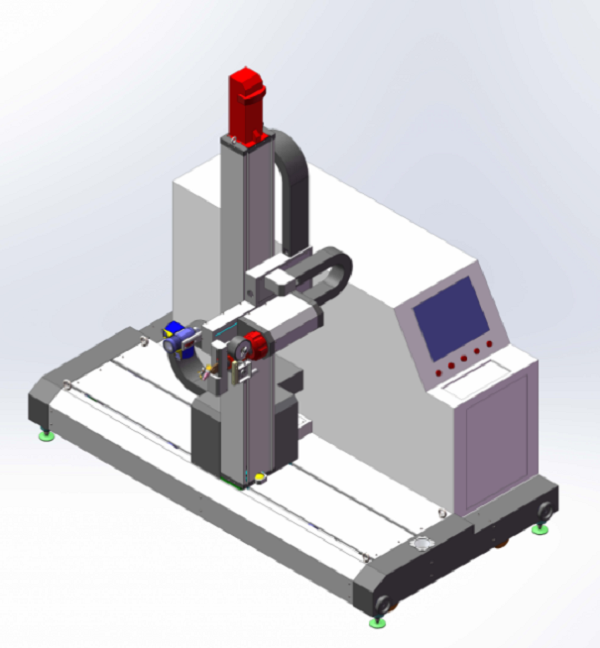

Automatic Tube-Plate Welding Robot

Scope of application

This robot is mainly designed for the welding of tube and plate on the shell and tube heat exchanger. It applies advanced vision positioning, laser vision tracking and intelligent control technologies to achieve real automatic tube-plate welding without manual operations.

Product features

• Automatic positioning and changing position: it applies advanced vision feedback technology to achieve non-contact positioning, which can avoid manual shift, insertion and extraction in mechanical positioning process. It makes the positioning process more quick and accurate.

• Laser vision measurement: it extracts the three dimensional information of the welding position automatically using laser vision system, which solves the problems caused by non-standard shape and wall thickness of the tube, and positioning error between the welding gun and the workpiece in the real production process.

• It can weld many kinds of workpieces, including steel bar, waist-shaped tube, oblate tube and some other non-circular workpieces.

•The welding head uses conventional high quality wire feeder, motion electromechanical components, which are more reliable and durable.

•Intelligent digital AC servo control system runs automatically. The operation process is easy, which can lower labour intensity and skill requirements.

| Model number | TPWR-5 | ||

| Welding material | Carbon steel, stainless steel, titanium alloy | Protective gas | Argon |

| Tube diameter | φ8~φ80 mm(customizable) | Cooling mode of the welding gun |

Water-cooling

|

| Tube position | Out of, parallel, inside of the plate | Welding gun obliquity | 0~30 degrees (adjustable) |

| Movement stroke(mm) | 1500(w) ×1800(h) ×280(z) | Welding speed | ≤12 rpm |

| Welding wire diameter | φ0.8.φ1.0mm | Equipment size(mm) | 2550×2800×1760 |

| Tungsten diameter | φ2.4~φ3.2mm | Equipment weight | 900kg |

| Welder rated current | 300A | ||

Welding Robot, Welding Machine, Head Of Welding Robot, Curved Plate Bevel Cutting Robot

Junfeng Machinery Co., Ltd. http://www.longxuanmachines.com